Reduce Carbon Footprint: Circular Economy in US Manufacturing

US manufacturers can significantly reduce their carbon footprint by adopting circular economy principles, focusing on waste reduction, resource efficiency, and product lifecycle extension.

US manufacturers are increasingly under pressure to reduce their environmental impact, and one of the most effective strategies is the adoption of circular economy principles. But how can US manufacturers reduce their carbon footprint through the adoption of circular economy principles? This article explores the opportunities and challenges associated with this transition.

Understanding the Circular Economy for US Manufacturers

The circular economy is a model of production and consumption that involves sharing, leasing, reusing, repairing, refurbishing and recycling existing materials and products as long as possible. In contrast, a traditional linear economy follows a ‘take-make-dispose’ model. For US manufacturers, embracing circularity means rethinking how products are designed, manufactured, used, and recovered, leading to significant environmental and economic benefits.

What is the Circular Economy?

The circular economy aims to minimize waste and maximize the value of resources. It’s about creating a closed-loop system where materials are kept in use for as long as possible, reducing the need for new raw materials and minimizing waste sent to landfills.

Why is it Important for US Manufacturers?

Adopting circular economy principles can help US manufacturers reduce their carbon footprint, lower costs, and improve their brand reputation. It also aligns with growing consumer demand for sustainable products and practices.

- Reduced Carbon Footprint: By using fewer raw materials and recycling more, manufacturers can significantly lower their carbon emissions.

- Cost Savings: Circular practices can lead to lower material costs and reduced waste disposal fees.

- Enhanced Brand Reputation: Consumers are increasingly favoring companies with strong sustainability commitments.

Implementing circular economy strategies requires a shift in mindset and operational practices, but the long-term benefits make it a worthwhile investment for US manufacturers aiming to lead in sustainability.

Designing for Circularity: A Key Strategy

One of the most critical steps in reducing the carbon footprint through circular economy principles is designing products for circularity. This involves creating products that are durable, repairable, reusable, and recyclable. By focusing on design, manufacturers can minimize waste and extend the lifespan of their products.

Durability and Longevity

Designing products to last longer reduces the need for frequent replacements, which in turn lowers the demand for new raw materials and energy-intensive manufacturing processes.

Repairability and Upgradability

Making products easy to repair and upgrade allows consumers to extend their use and avoid discarding them prematurely. This requires designing products with modular components and readily available replacement parts.

- Modular Design: Products with modular components are easier to repair and upgrade.

- Standardized Parts: Using standardized parts ensures that replacements are readily available.

- Easy Disassembly: Designing products for easy disassembly facilitates recycling and material recovery.

By incorporating these design principles, US manufacturers can create products that are not only environmentally friendly but also more appealing to consumers who value durability and longevity.

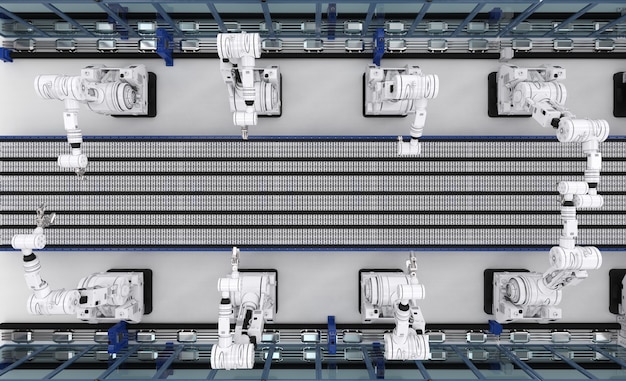

Implementing Closed-Loop Manufacturing

Closed-loop manufacturing is a system where waste materials are reintroduced into the production process, minimizing the need for new raw materials and reducing waste. This approach can significantly lower a manufacturer’s environmental impact while creating new revenue streams.

Waste as a Resource

Treating waste as a valuable resource involves identifying materials that can be reused or recycled within the manufacturing process. This requires careful waste management and sorting systems.

On-Site Recycling

Implementing on-site recycling programs allows manufacturers to process waste materials directly, reducing transportation costs and ensuring that materials are properly recycled.

Closed-loop manufacturing initiatives can provide US manufacturers with a competitive advantage by reducing costs, improving resource efficiency, and demonstrating a commitment to sustainability. It also creates opportunities for innovation in material processing and product design.

Embracing Product Stewardship and Extended Producer Responsibility

Product stewardship involves manufacturers taking responsibility for the environmental impact of their products throughout their entire lifecycle, from design to disposal. Extended Producer Responsibility (EPR) is a policy approach that makes manufacturers responsible for the end-of-life management of their products.

The Role of Product Stewardship

Product stewardship encourages manufacturers to design products that are easier to recycle, reuse, or remanufacture. It also promotes collaboration between manufacturers, retailers, and consumers to ensure proper disposal and recycling.

Understanding Extended Producer Responsibility (EPR)

EPR policies require manufacturers to finance and manage the collection, recycling, and disposal of their products. This incentivizes manufacturers to design products that are easier and cheaper to recycle.

- Financial Responsibility: Manufacturers bear the costs of recycling and disposal.

- Operational Responsibility: Manufacturers manage the collection and processing of their products.

- Design for Environment: EPR encourages manufacturers to design products with the environment in mind.

By embracing product stewardship and EPR, US manufacturers can demonstrate their commitment to environmental responsibility and contribute to a more sustainable economy. It also encourages innovation in product design and waste management.

Collaborating for a Circular Supply Chain

Creating a circular economy requires collaboration across the entire supply chain, from raw material suppliers to end-of-life processors. By working together, businesses can optimize resource use, reduce waste, and create new opportunities for innovation.

Building Partnerships with Suppliers

Manufacturers can work with their suppliers to source more sustainable materials, reduce packaging waste, and implement closed-loop systems. This requires open communication and a shared commitment to sustainability.

Engaging Consumers

Educating consumers about the benefits of circularity and encouraging them to participate in recycling and reuse programs is essential. This can involve providing clear instructions for proper disposal and incentivizing consumers to return products for recycling or remanufacturing.

Collaboration is key to creating a truly circular economy. By working together, businesses can overcome barriers, share best practices, and drive innovation in sustainability.

Overcoming Challenges and Measuring Success

While the benefits of adopting circular economy principles are clear, US manufacturers may face several challenges in implementation. These include technological limitations, regulatory barriers, and financial constraints. However, by addressing these challenges and measuring progress, manufacturers can successfully transition to a more circular business model.

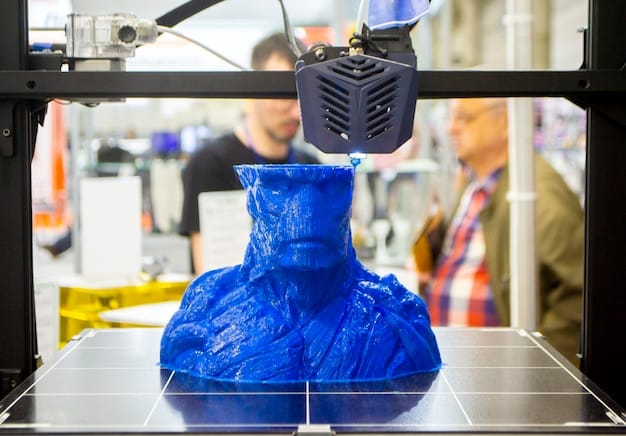

Addressing Technological Limitations

Investing in new technologies and infrastructure is essential for implementing circular economy practices. This may involve adopting advanced recycling technologies, developing new materials, and investing in closed-loop manufacturing systems.

Navigating Regulatory Barriers

Manufacturers need to be aware of and comply with environmental regulations related to waste management, recycling, and product stewardship. Engaging with policymakers to advocate for supportive policies can also be beneficial.

- Technological Investments: Investing in advanced recycling and manufacturing technologies.

- Regulatory Compliance: Adhering to environmental regulations and advocating for supportive policies.

- Performance Indicators: Tracking progress with key environmental and economic metrics.

By addressing these challenges and measuring progress, US manufacturers can successfully transition to a more circular business model and achieve significant environmental and economic benefits.

| Key Aspect | Brief Description |

|---|---|

| 🔄 Circular Design | Creating durable, repairable, and recyclable products. |

| 🏭 Closed-Loop Manufacturing | Reintroducing waste materials into the production process. |

| 🤝 Collaboration | Working with suppliers and consumers for optimal resource use. |

| 🌱 Product Stewardship | Taking responsibility for the entire lifecycle of products. |

Frequently Asked Questions

▼

The main principles include designing out waste and pollution, keeping products and materials in use, and regenerating natural systems. It’s about shifting from a linear “take-make-dispose” model to a circular one.

▼

By reducing the need for raw materials extraction, minimizing waste sent to landfills, and promoting energy-efficient manufacturing processes, the circular economy significantly lowers carbon emissions.

▼

Product stewardship involves manufacturers taking responsibility for the environmental impact of their products throughout their entire lifecycle, from design to disposal, ensuring sustainable practices.

▼

Closed-loop manufacturing reduces waste, lowers material costs, improves resource efficiency, and enhances brand reputation by demonstrating a commitment to sustainability and environmental responsibility.

▼

Manufacturers can track key environmental and economic metrics, such as waste reduction rates, energy consumption, material usage, and cost savings, to assess the effectiveness of their circular economy efforts.

Conclusion

Adopting circular economy principles offers a significant opportunity for US manufacturers to reduce their carbon footprint, improve resource efficiency, and enhance their competitiveness. By focusing on design for circularity, implementing closed-loop manufacturing, embracing product stewardship, and collaborating across the supply chain, manufacturers can create a more sustainable and resilient future.