Enhancing Biofuel: How Bioreactors Revolutionize Algae Production

Bioreactors enhance the efficiency of algae-based biofuel production by providing controlled environments that optimize algae growth, nutrient delivery, and light exposure, leading to significantly higher yields and reduced contamination compared to traditional open pond systems.

The quest for sustainable energy sources has led researchers and businesses to explore the potential of algae as a biofuel feedstock. But how can we make algae-based biofuel production truly efficient and competitive? The answer lies, in part, in innovative technologies like bioreactors. This article looks into how can bioreactors improve the efficiency of algae-based biofuel production?, transforming the landscape of green energy.

Understanding Algae as a Biofuel Source

Algae have emerged as a promising alternative to traditional biofuel feedstocks due to their rapid growth rates, high lipid content (which can be converted into biodiesel), and ability to grow in diverse environments. Unlike conventional biofuel crops, algae do not compete with agricultural land used for food production. However, the successful and economical conversion of algae into biofuel hinges on efficient cultivation methods.

The Promise of Algae

Algae offer several key advantages as a biofuel source. They can accumulate substantial amounts of lipids or carbohydrates, which can then be processed into biofuels. Their ability to utilize non-arable land and various water sources, including seawater and wastewater, minimizes competition with traditional agriculture and can even contribute to wastewater treatment.

- High biomass productivity compared to terrestrial crops.

- Ability to grow on non-arable land and in diverse water sources.

- Potential for carbon sequestration during growth.

Yet, despite these advantages, scaling up algae biofuel production has faced challenges, particularly in achieving cost-effectiveness and sustainable yields when using open pond systems.

Limitations of Open Pond Systems

The main limitation to open pond systems is the limited control over growing conditions. Environmental factors like rain, temperature fluctuations, nutrient availability, pests, and contamination by other microorganisms can drastically influence the algae yield. Open ponds also require large land areas and often result in lower biomass concentrations compared to controlled environments.

The integration of bioreactors represents a significant step forward, addressing many of the shortcomings inherent in open cultivation systems. Bioreactors offer unprecedented control over the algae’s environment, leading to optimized growth rates and yields.

In conclusion, algae serves as an exciting base for biofuel. However, the limitations of the traditionally used open pond systems underscore the need for more advanced cultivation techniques, which brings us to the benefits of bioreactors.

What are Bioreactors and How Do They Work?

Bioreactors, also known as photobioreactors (PBRs) in the context of algae cultivation, are closed and controlled systems designed to cultivate microorganisms, including algae, under optimized conditions. Unlike open pond systems, bioreactors offer precise control over key environmental factors.

Key Components and Features

A typical bioreactor system consists of several essential components, each playing a crucial role in sustaining optimal algae growth. This includes precise management of light, temperature, and carbon dioxide to guarantee the right conditions are met.

- Precise light delivery systems (natural sunlight or artificial lighting).

- Temperature control mechanisms to maintain optimal ranges.

- Nutrient delivery and pH regulation systems.

These components work in synergy to create a tailored environment that maximizes algae productivity while minimizing contamination and environmental variability.

Types of Bioreactors Used for Algae Cultivation

Several types of bioreactors are utilized in algae cultivation, each with its own advantages and disadvantages. The choice of reactor depends on the specific algae strain, production scale, and desired biofuel product.

Different bioreactor designs include:

- Tubular bioreactors: offer high surface area-to-volume ratios for efficient light penetration

- Flat-panel bioreactors: maximize light exposure and provide good temperature control

- Column bioreactors: suitable for high-density cultures

Each design impacts light exposure, mixing efficiency, temperature control, and scalability, which in turn affect overall productivity and cost-effectiveness. For example, tubular bioreactors are known for their high surface area, which allows for better light penetration; however, they can be less efficient in temperature regulation than flat-panel reactors, which are designed to have a larger surface area for cooling.

In essence, bioreactors provide a controlled, customizable environment that enhances algae development and biomass production, a fundamental element in algae-based biofuel production.

The Core Benefits of Bioreactors in Algae Biofuel Production

One of the primary answers to the question: “how can bioreactors improve the efficiency of algae-based biofuel production?”, lies in greatly improved output compared to traditional methods. By offering regulated environments, bioreactors improve algae growth conditions, leading to more biofuel output.

Enhanced Productivity

Bioreactors significantly enhance algae productivity through several mechanisms. Consistent light supply and optimized nutrient control allow for higher growth rates and biomass yields. The closed nature of the system also minimizes water loss through evaporation and reduces the risk of contamination, leading to healthier and more robust algae cultures.

By optimizing light and managing nutrients, bioreactors create an environment conducive to rapid and efficient algae growth. These elements dramatically improve the productivity of biofuels.

Reduced Contamination

Contamination from unwanted microorganisms, pests, and competing algae species is a major challenge in open pond systems. Bioreactors, being closed systems, drastically reduce the risk of contamination, leading to more stable and predictable production cycles.

Purity in algae cultures directly translates to more efficient biofuel production. By maintaining high purity, bioreactors ensure that the algae efficiently convert resources into lipids or carbohydrates suitable for biofuel extraction, without the yield diminishing due to contamination.

To sum it up, the use of bioreactors in algae biofuel production improves productivity by controlling the environment and reducing the risk of contamination thus, yielding more stable algae cultures.

Optimizing Growth Conditions in Bioreactors

Bioreactors offer unparalleled opportunities to fine-tune growth conditions for algae, allowing producers to tailor environmental parameters to the specific needs of different algal strains. Optimizing growth conditions includes an extensive analysis of multiple factors.

Light Management

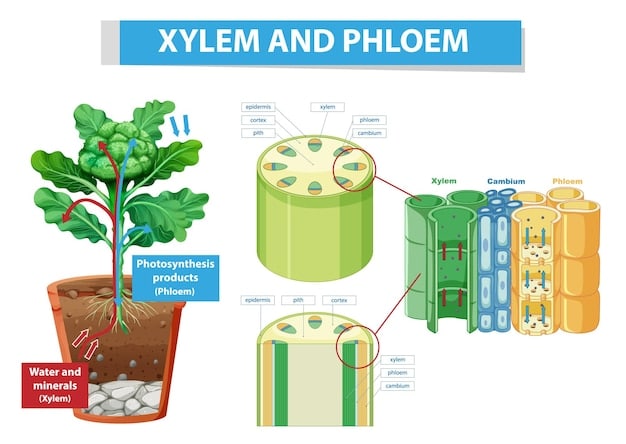

Light is a critical factor in algae growth. Bioreactors allow for precise control over light intensity, wavelength, and photoperiod, ensuring that algae receive the optimal amount of light for photosynthesis without experiencing photoinhibition (damage caused by excessive light). Light management is a central element in maximizing algae growth potential.

- Strategic use of artificial lighting systems (LEDs) to supplement or replace natural sunlight.

- Optimization of light distribution within the bioreactor to ensure uniform exposure for all algae cells.

- Dynamic adjustment of light intensity and photoperiod to match the growth stage of the algae.

Nutrient Control and Delivery

Optimal nutrient supply is equally important for algae growth. Bioreactors facilitate precise control over nutrient concentrations, ratios, and delivery rates, preventing nutrient limitations or excesses that can inhibit growth or alter lipid profiles. This is the key to ensuring that algae have all the resources they need for optimal biological activity.

Nutrient control strategies include:

- Real-time monitoring of nutrient levels and automated adjustment of supply rates.

- Formulation of customized nutrient solutions tailored to the specific needs of different algae strains.

- Implementation of closed-loop nutrient recycling systems to minimize waste and reduce costs.

Temperature and pH Regulation

Maintaining stable temperature and pH levels is crucial for enzymatic activity and overall algae health. Bioreactors are equipped with sophisticated temperature control systems and pH sensors that ensure these parameters remain within the optimal range for algae growth. Temperature and pH control are essential for stability and efficiency.

With optimized light, nutrients, and temperature control, bioreactors enable algae to thrive and accumulate biomass and lipids more efficiently, transforming them into efficient powerhouses for biofuel production.

Overcoming Challenges and Promoting Scalability

In order to answer the question, how can bioreactors improve the efficiency of algae-based biofuel production, it is important to address the challenges and scalability aspects. Despite the significant advantages of bioreactors, several challenges must be addressed to promote widespread adoption and scalability.

High Initial Investment and Operating Costs

The initial investment in bioreactor systems can be substantial, due to the advanced technology and materials involved. Operating costs, including energy consumption for lighting, temperature control, and mixing, also contribute to the overall economic burden. It’s important to consider energy-efficient solutions to minimize costs.

- Develop more cost-effective bioreactor designs using innovative materials and construction techniques.

- Implement energy-efficient lighting systems (e.g., LEDs) and temperature control strategies.

- Optimize nutrient recycling and waste management to reduce resource consumption.

Scale-Up Strategies and Considerations

Scaling up algae biofuel production from laboratory-scale bioreactors to commercial facilities requires careful planning and optimization. Issues such as light penetration, mixing efficiency, and temperature control become more complex as the reactor volume increases. However, many strategies can be implemented.

Scalability plans involve:

- Developing modular bioreactor systems that can be easily expanded.

- Optimizing reactor geometry and mixing systems to ensure uniform light distribution and nutrient availability at larger scales.

- Implementing robust monitoring and control systems to maintain optimal growth conditions in large-scale bioreactors.

Integration with Renewable Energy Sources

To enhance the sustainability of algae biofuel production, it is essential to integrate bioreactors with renewable energy sources. Using solar panels to power lighting and temperature control systems can significantly reduce the carbon footprint of the entire process. Renewable energy integration is vital for sustainable biofuel production.

Overall, addressing the challenges and strategically approaching scalability are important when evaluating how bioreactors can improve the efficiency of algae-based biofuel production. Efficient strategies will solidify algae’s role in the future of green energy.

Future Trends and Innovations in Bioreactor Technology

The field of bioreactor technology is constantly evolving, with ongoing research and development efforts focused on improving efficiency, reducing costs, and enhancing sustainability.

Advanced Materials and Designs

New materials, such as transparent polymers and nanocomposites, are being explored to enhance light penetration and reduce shading within bioreactors. Innovative designs, such as microfluidic bioreactors and 3D-printed reactors, are also emerging as potential game-changers. Material and design innovation offers possibilities.

- Development of self-cleaning bioreactor surfaces to minimize biofouling and reduce maintenance requirements.

- Integration of smart sensors and AI-powered control systems to enable real-time optimization of growth conditions

- Exploration of hybrid bioreactor systems that combine the advantages of different reactor types.

Genetic Engineering of Algae

Genetic engineering plays a crucial role in enhancing the performance of algae strains in bioreactors. Researchers are developing genetically modified algae with improved lipid production, enhanced tolerance to stress, and increased resistance to contamination. Genetically enhanced algae offer improved performance under varying conditions.

The genetic modification of algae involves:

- Optimizing lipid biosynthesis pathways to increase lipid yields and alter fatty acid profiles.

- Enhancing carbon dioxide fixation to increase biomass productivity.

- Strengthening cell walls to improve resistance to shear stress in turbulent bioreactor environments.

Integrated Biorefinery Concepts

The future of algae biofuel production lies in integrated biorefinery concepts, where algae biomass is used for multiple purposes beyond biofuel production. Integrated biorefineries can generate a diverse range of products, including bioplastics, animal feed, and high-value biochemicals, maximizing the economic and environmental benefits of algae cultivation.

All things considered, the progress in advanced materials, genetic engineering, and integrated biorefinery ideas will fuel future growth in this industry.

| Key Point | Brief Description |

|---|---|

| 🌱 Productivity Boost | Bioreactors optimize conditions for algae growth leading to significant increase in biofuel output. |

| 🛡️ Contamination Control | Closed systems reduce the risk of contamination, ensuring purer algae cultures and more efficient biofuel production. |

| 💡 Light Management | Precise control over light exposure maximizes photosynthesis and biomass yield. |

| 💰 Renewable Integration | Combining bioreactors with renewable energy sources reduces overall carbon footprint. |

Frequently Asked Questions

▼

Bioreactors offer higher yields, reduce contamination risks, and allow precise control over growth conditions compared to traditional open pond systems. This leads to more efficient biofuel production.

▼

The light management system uses artificial lighting to ensure that algae receive the optimal amount of light for photosynthesis. This is managed in a controlled environment at all times.

▼

Genetic engineering can enhance lipid production, improve stress tolerance, and increase resistance to contamination in algae strains, making them more effective for biofuel production. This boosts efficiency.

▼

Yes, with modular systems that are easily expanded. Careful planning and optimization also allows for commercial facilities. Light penetration and mixing efficiency are key when planning scalability.

▼

Integrated biorefineries use algae biomass for producing bioplastics, animal feed, and high-value biochemicals, in addition to biofuel, which enhances economic and ecological benefits. This also improves profitability.

Conclusion

In conclusion, the use of bioreactors represents a significant advancement in algae-based biofuel production. By providing optimized growth conditions, minimizing contamination, and facilitating the integration of renewable energy sources, bioreactors hold the key to unlocking the full potential of sustainable algae biofuels.