Anaerobic Digestion: A Guide for US Farmers on Renewable Energy and Waste Management

Anaerobic digestion offers US farmers a sustainable solution for renewable energy production and efficient waste management by converting organic materials into biogas and valuable byproducts, contributing to environmental benefits and potential revenue streams.

For United States farmers, the intersection of agriculture and sustainability is becoming increasingly important. How can farms become more environmentally friendly while also boosting their bottom line? One promising avenue lies in **anaerobic digestion for renewable energy production and waste management**.

Understanding Anaerobic Digestion

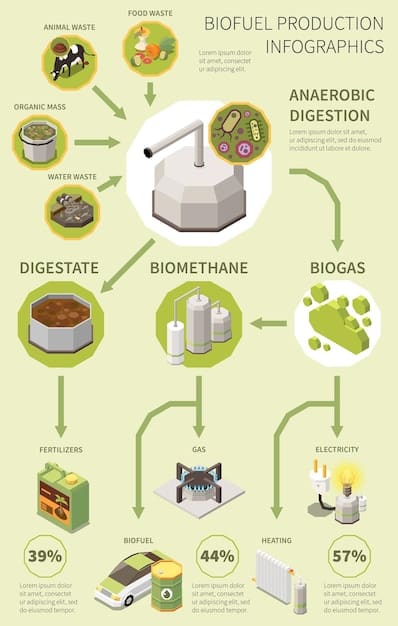

Anaerobic digestion is a naturally occurring process where microorganisms break down organic material in the absence of oxygen. This decomposition produces biogas, a mixture primarily of methane and carbon dioxide, which can be used as a renewable energy source. For US farmers, this presents an opportunity to convert waste products into valuable energy.

The Science Behind Anaerobic Digestion

The anaerobic digestion process involves several stages, each facilitating the breakdown of organic matter by different groups of microorganisms. The key output is biogas, but the process also yields digestate, a nutrient-rich byproduct that can be used as fertilizer.

Feedstocks for Anaerobic Digesters

A wide range of organic materials can serve as feedstock for anaerobic digesters. These include:

- Manure from livestock operations

- Crop residues, such as corn stalks and wheat straw

- Food processing waste

- Energy crops grown specifically for digestion

Using these materials not only provides a source of energy but also helps to mitigate waste disposal issues on farms.

Anaerobic digestion, therefore, offers a practical approach to managing waste, decreasing environmental impact, and creating sustainable energy resources on farms in the US.

Benefits of Anaerobic Digestion for US Farms

Implementing anaerobic digestion systems on US farms can yield multiple benefits, ranging from environmental to economic. These advantages make it an attractive option for farms looking to improve sustainability and profitability.

Renewable Energy Production

Biogas produced through anaerobic digestion can be used to generate electricity, heat, or transportation fuel. This reduces reliance on fossil fuels and lowers greenhouse gas emissions.

Waste Management

Anaerobic digestion helps manage organic waste, reducing odors, pathogens, and the volume of material needing disposal. This is particularly beneficial for large livestock operations.

Economic Opportunities

Farmers can generate revenue by selling the biogas produced or using it to offset energy costs. Additionally, the digestate byproduct can be sold as fertilizer, creating another income stream.

- Reduced energy bills

- Additional revenue from biogas and digestate sales

- Potential for carbon credits

These benefits make anaerobic digestion a compelling investment for US farms, aligning environmental stewardship with financial gains.

Types of Anaerobic Digestion Systems

Different types of anaerobic digestion systems are available, each suited to specific farm sizes, types of feedstock, and operational goals. Understanding these systems can help farmers choose the best option for their needs.

Covered Lagoon Digesters

These are often the most budget-friendly to set up and are best for farms with liquid manure. Lagoons are covered with an airtight material, capturing biogas from the manure’s natural decomposition. This trapped biogas can then be collected and burned to produce electricity.

Complete Mix Digesters

Complete mix digesters heat and frequently mix their contents to raise biogas output. They can handle a variety of waste materials, including yard waste, leftover food, fats, grease, and industrial byproducts. This helps boost their biogas production.

Plug Flow Digesters

These digesters are long, enclosed tanks where waste is fed continuously at one end and removed from the other. They work best with thick, solid materials such as manure mixed with straw, bedding, or food scraps. Plug flow digesters are designed to handle waste that requires more than twenty days to digest thoroughly.

Selecting the right anaerobic digestion system is crucial for maximizing efficiency, minimizing costs, and ensuring long-term sustainability for US farms.

Implementing Anaerobic Digestion on US Farms

Implementing an anaerobic digestion system requires careful planning, investment, and ongoing management. US farmers need to consider several factors to ensure a successful and sustainable operation.

Planning and Design

Proper planning involves assessing the available feedstock, selecting the appropriate digester technology, and designing the system to meet energy and waste management needs. Engaging with experts and consultants is crucial.

Regulatory Considerations

Farmers must comply with federal, state, and local regulations related to air emissions, water quality, and waste management. Understanding these requirements is essential for avoiding penalties and ensuring environmental compliance.

Financial Investment and Incentives

The initial investment for an anaerobic digestion system can be substantial. However, various grants, loans, and tax incentives are available to help offset the costs. Exploring these financial opportunities is vital for making the project economically viable.

Effective implementation of anaerobic digestion systems can transform US farms into more sustainable, efficient, and profitable operations.

Challenges and Solutions in Anaerobic Digestion

While anaerobic digestion offers numerous benefits, it also presents certain challenges. Understanding these challenges and implementing effective solutions is essential for the successful adoption of this technology by US farmers.

High Initial Costs

The upfront investment for anaerobic digestion systems can be a barrier for many farmers. Solutions include seeking grants, financing options, and exploring collaborative projects with neighboring farms.

Technical Complexity

Operating and maintaining an anaerobic digestion system requires technical expertise. Farmers can address this by hiring trained personnel, partnering with experienced operators, and participating in training programs.

Feedstock Variability

The composition and quality of feedstock can vary, affecting biogas production. Implementing feedstock management strategies, such as mixing different types of organic materials, can help stabilize the digestion process.

- Securing funding through grants and incentives

- Collaborating with other farms to share resources

- Investing in training and technical support

Overcoming these challenges will enable more US farmers to harness the full potential of anaerobic digestion.

Case Studies of Successful Anaerobic Digestion Projects

Examining successful anaerobic digestion projects can provide valuable insights and inspiration for US farmers considering this technology. These case studies demonstrate the practical benefits and potential of anaerobic digestion in various agricultural settings.

Example 1: Dairy Farm in Wisconsin

A dairy farm in Wisconsin implemented an anaerobic digestion system to process manure from its herd. The biogas produced generates electricity, which is used to power the farm and sold back to the grid. The digestate is used as fertilizer, reducing the need for chemical inputs.

Example 2: Hog Farm in Iowa

A hog farm in Iowa installed an anaerobic digester to manage manure and reduce odor emissions. The biogas is used to heat the farm buildings, saving on energy costs. The digestate is applied to crop fields, improving soil health and reducing fertilizer expenses.

Example 3: Mixed Crop and Livestock Farm in California

A mixed crop and livestock farm in California uses an anaerobic digester to process agricultural residues and livestock manure. The biogas is used to fuel vehicles, reducing reliance on fossil fuels. The digestate is composted and used as a soil amendment.

These case studies illustrate the versatility and effectiveness of anaerobic digestion in different farming contexts, highlighting the potential for US farmers to achieve both environmental and economic benefits.

| Key Point | Brief Description |

|---|---|

| 💡 Renewable Energy | Anaerobic digestion produces biogas, usable for electricity, heat, or fuel. |

| ♻️ Waste Management | Reduces odors and pathogens, turning waste into valuable resources. |

| 💰 Economic Benefits | Generates revenue from biogas and digestate, lowering energy costs. |

| 🌱 Digestate Fertilizer | Nutrient-rich byproduct replaces chemical fertilizers, improving soil. |

Frequently Asked Questions

▼

Anaerobic digestion is a biological process where microorganisms break down organic material in the absence of oxygen, producing biogas and digestate.

▼

Various organic materials, including manure, crop residues, food processing waste, and energy crops, can be used as feedstock for anaerobic digestion.

▼

Benefits include renewable energy production, efficient waste management, reduced greenhouse gas emissions, and new revenue streams from biogas and digestate.

▼

The initial investment varies depending on the size and type of system. However, grants, loans, and tax incentives can help offset these costs.

▼

Digestate is a nutrient-rich byproduct of anaerobic digestion that can be used as a fertilizer, providing essential nutrients to crops and improving soil health.

Conclusion

Anaerobic digestion presents a significant opportunity for US farmers to enhance sustainability, reduce waste, and create new revenue streams. By understanding the process, exploring the different types of systems, and addressing potential challenges, farmers can successfully implement this technology and contribute to a more sustainable future.